Enzymes in cage

As biocatalysts, enzymes accelerate many chemical reactions. Researchers at the Karlsruhe Institute of Technology (KIT) have now incorporated enzymes into metal-organic cages (MOFs). They then demonstrated for the first time that the stabilization provided by these framework structures is even sufficient for use of the enzymes in a continuously operated reactor. Also new: The enzymes embedded in MOFs can be used not only in aqueous solvents, but also in organic solvents. The researchers report in the journal “Angewandte Chemie”.

They are considered to be true multifunctional talents: as catalysts, enzymes accelerate many chemical reactions. In organisms, they are involved in vital processes. In technology and industry, they are tools of white biotechnology that help save energy and conserve resources. Enzymes in detergents, for example, dissolve dirt at low temperatures. Enzymes are also used in environmental technology, food processing, drug production, medical diagnostics and many other areas.

Enzymes are mostly proteins. In order to exploit the potential of these giant molecules outside biological contexts in so-called cell-free biotechnology, they must be stabilized and integrated into efficient reactor systems. This challenge, which is central to white biotechnology, has already been overcome in many cases in aqueous solvents. In organic solvents, on the other hand, destabilization or denaturation often occurs — the catalytic properties are lost.

Researchers at the Institut für Funktionelle Grenzflächen (IFG), at the Institute of Nanotechnology and the Institute of Biological Interfaces 1 — Biomolecular Micro- and Nanostructures of KIT have now succeeded in stabilizing enzymes in such a way that they can be used in both aqueous and organic solvents. Thus, they were able to demonstrate for the first time a continuous enzyme reactor system with high productivity and stability. The scientists report on this in the journal “Angewandte Chemie”.

MOFs simplify separation of catalysts and products

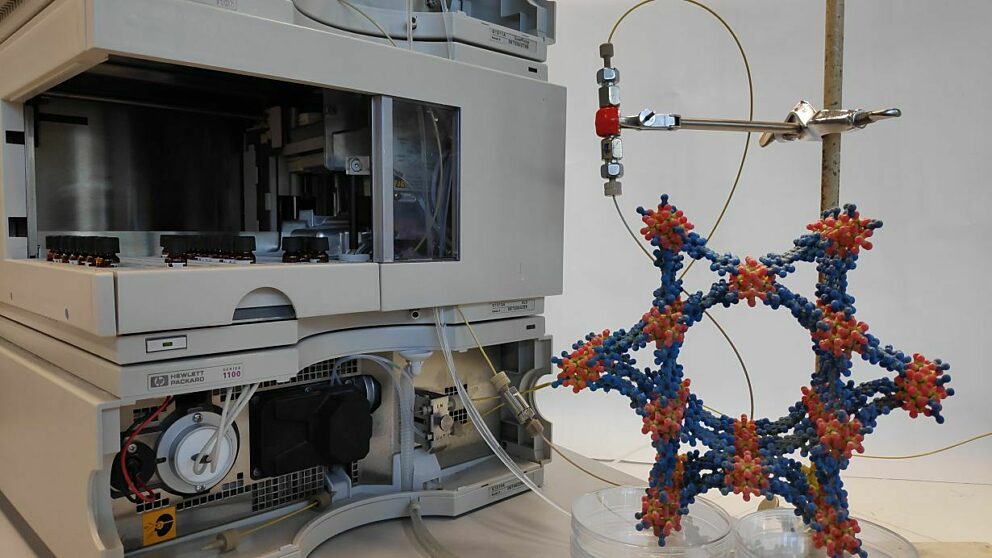

The innovative reactor system is based on metal-organic frameworks (MOFs). These are frameworks consisting of metallic nodes and organic connecting struts, which are characterized by crystalline structures and defined pore sizes. Through different combinations of metal building blocks and organic ligands as well as variations in pore size, MOFs can be tailored for very different applications. When used cell-free with enzymes, they act like cages. “We get the enzymes to diffuse individually into the pores of the MOFs, that is, to slip into the cage voluntarily, so to speak,” explains Professor Christof Wöll, head of the IFG. “The MOFs act as armor, protecting these sensitive biomolecules and preventing denaturation.” Thanks to the porosity of MOFs, the transport of reactants, the substances consumed during chemical reactions, and products formed in the process can be better controlled. In addition, MOFs simplify the laborious separation of catalyst and products, as explained by Professor Matthias Franzreb, deputy director of the IFG and co-author of the study.

The Karlsruhe researchers demonstrated the time- and cost-efficient fabrication of an enzyme MOF flow reactor. In this process, the stability of the immobilized enzyme was about 30 times higher than that of the free enzyme. The catalytic activity was about 30 percent compared to the free enzyme — quite a high value considering the deformation of the enzyme embedded in the MOF pores. The study was conducted in the context of the Cluster of Excellence “3D Matter Made to Order” of KIT and Heidelberg University and the Helmholtz program “Materials Systems Engineering”. In further work on the topic, it is planned to use computer-based methods to modify the MOFs in such a way that deformation through the pores does not lead to a reduction but to an increase in activity.

As “The Research University in the Helmholtz Association”, KIT creates and communicates knowledge for society and the environment. Its goal is to make significant contributions to global challenges in the fields of energy, mobility, and information. To this end, about 9,800 employees cooperate on a broad disciplinary basis in natural sciences, engineering, economics, and humanities and social sciences. KIT prepares its 22,300 students for responsible tasks in society, industry, and science through research-oriented university studies. KIT’s innovative activities bridge the gap between knowledge and application for the benefit of society, economic prosperity, and the preservation of our natural resources. KIT is one of the German universities of excellence.

Source

Original publication (Open Access):

Raphael Greifenstein, Tim Ballweg, Tawheed Hashem, Eric Gottwald, David Achauer, Frank Kirschhöfer, Michael Nusser, Gerald Brenner-Weiß, Elaheh Sedghamiz, Wolfgang Wenzel, Esther Mittmann, Kersten S. Rabe, Christof M. Niemeyer, Matthias Franzreb, Christof Wöll: MOF-hosted enzymes for continuous flow catalysis in aqueous and organic solvents. Angewandte Chemie, International Edition. 2022. DOI: 10.1002/anie.202117144

https://onlinelibrary.wiley.com/doi/10.1002/anie.202117144